Key Manufacturing Sites|Industrial Automation Group Suzhou Metrologic Plant

Established in 1999, Honeywell Industrial Automation Group's Suzhou Metrologic Plant (hereinafter referred to as “IA Suzhou Plant”) is located in Suzhou Industrial Park and employs more than 1,300 people. The factory is responsible for the production of automatic identification and data collection products, including barcode scanners, barcode label printers, mobile data terminals and etc. Most of them are used in industrial manufacturing, logistics, warehousing, medical, e-commerce, retailers and others, helping to improve efficiency in various industries. The factory was recognized as a “Green Factory” demonstration enterprise by China General Office of the Ministry of Industry and Information Technology in 2018.

Our Products

The iconic product, Xenon Power (1950/1952 series), was developed based on previous Xenon products, with longer reading distance, and faster decoding speed. It performs extraordinarily with ambiguous or damaged barcodes.

The EDA52 mobile computer is a durable and flexible productivity device that runs on the Mobility Android platform. It provides dependable performance, data connectivity, and communications for frontline workers in retail, logistics, healthcare applications, and field work.

PX240/PD45 series are label printers for industrial use, suitable for sectors such as manufacturing, retail logistics, medical hospitals, and government departments. They can print using thermal and thermal transfer methods.

The N6803 scanning engine, with built-in dual cameras with bi-focal lengths, combines ultra-thin size and superb performance to empower mobile terminals with high-speed, long-range scanning capability. It can read barcodes of over 10 meters-length, scan document or signature, recognize OCR characters, and perform machine learning abilities.

We are Green Factory!

In October 2018, IA Suzhou plant was shortlisted for the 2018 Green Manufacturing Demonstration List announced by China General Office of the Ministry of Industry and Information Technology. It was also recognized as one of the state-level “Green Factories”.

The plant always operates with strong adherence to environmental protection and the concept of sustainable development. Its advanced process, stable quality system and lean manufacturing model, operation and HSE management all reinforce its focus on sustainable development. The plant is committed to promoting sustainable transformation and upgrading of industrial manufacturing, helping enterprises, society and the environment to jointly achieve sustainable development.

The factory has taken the path of “low cost, high benefit, low emission and sustainability” by encouraging the use of solar energy, improving and replacing energy-efficient lighting fixtures, reclaiming waste heat from air compressors, implementing digital energy management system and ISO50001 energy management system, etc. It is practicing energy conservation and emission reduction, supporting the national “dual carbon” policy, and helping Honeywell achieve its sustainable development goals.

Our efforts

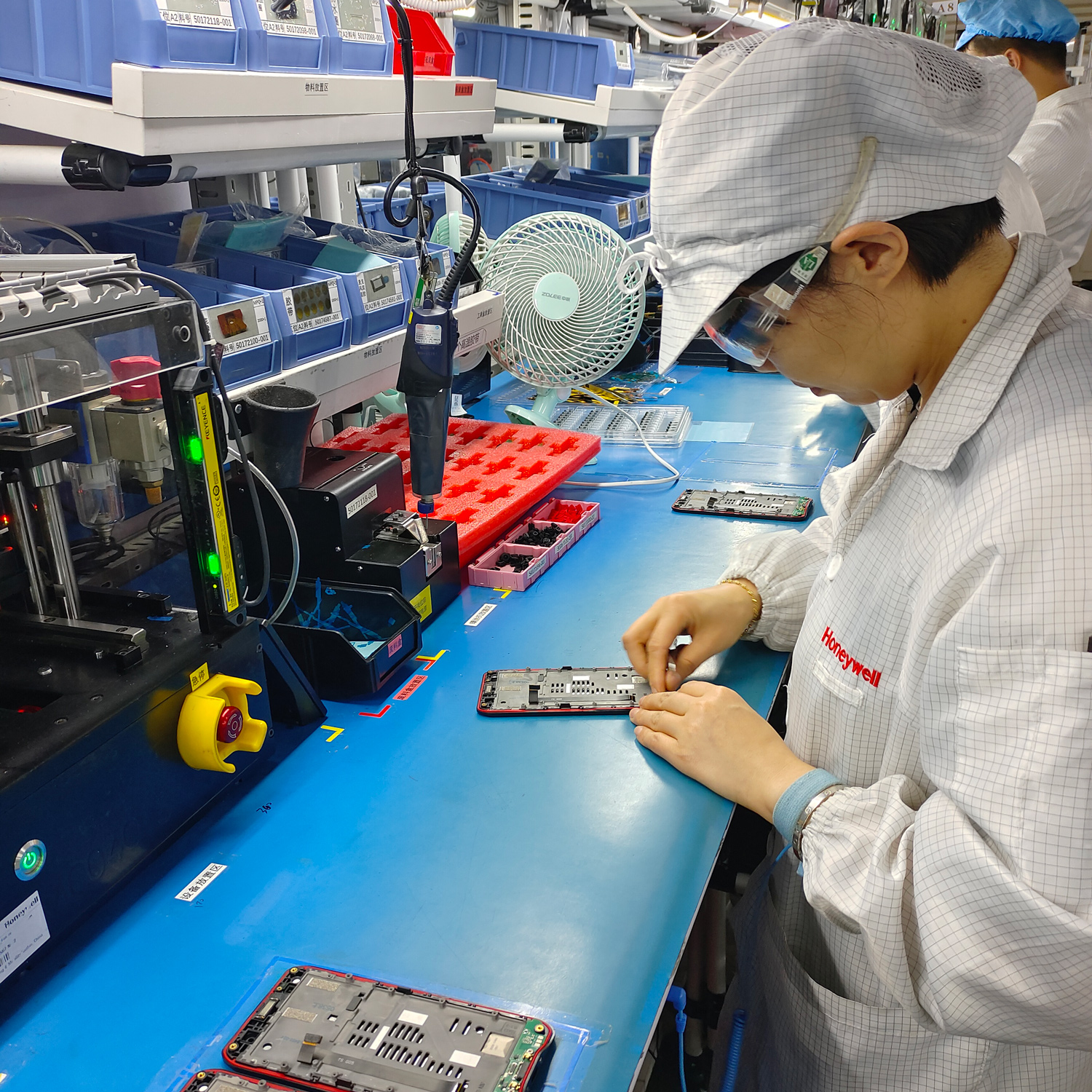

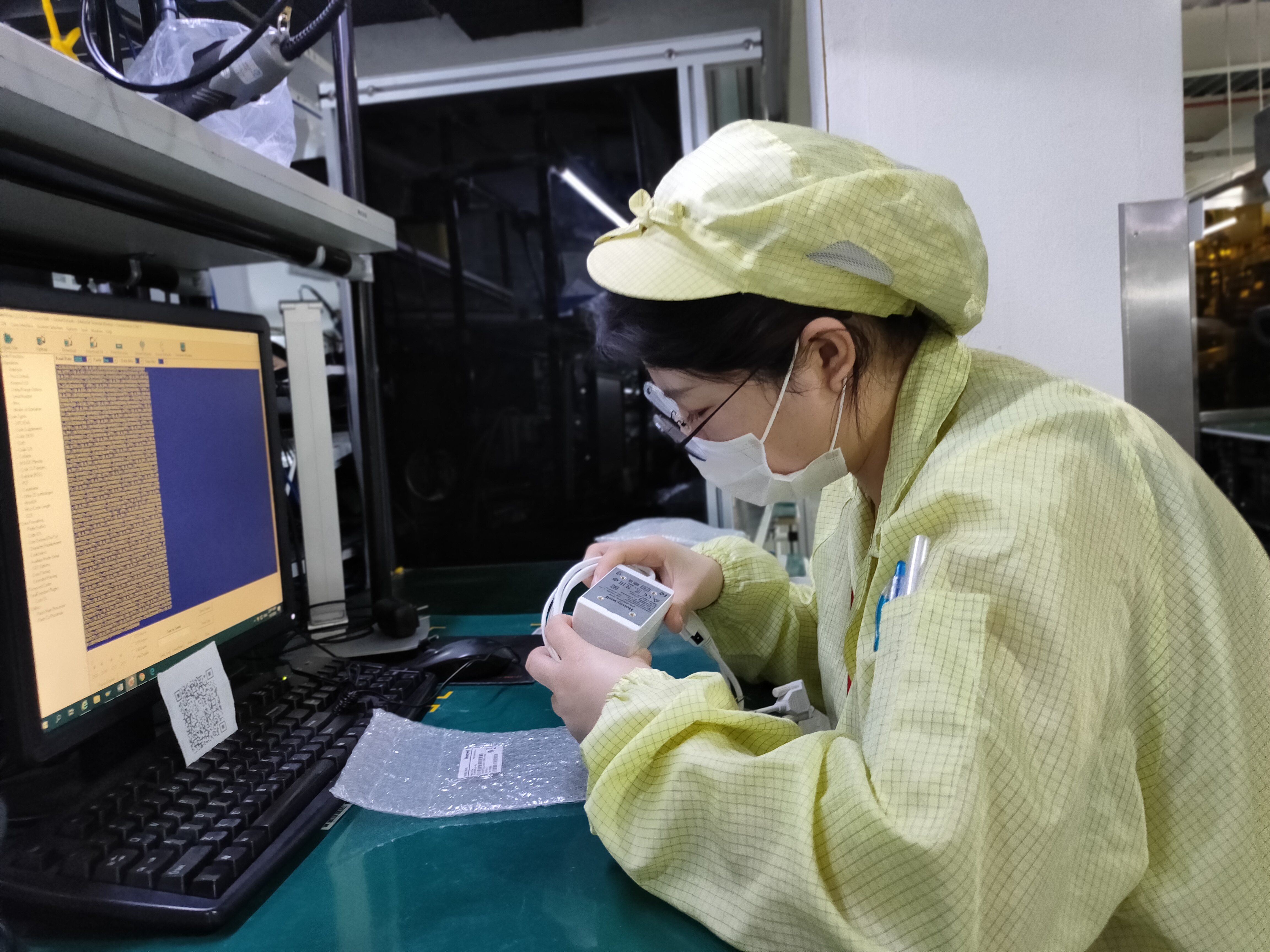

Our superb technology and wonderful colleagues produce high-quality products.

1 - Material delivered by driverless vehicle

2 - Collecting material

3 - Production line workers

4 - Quality check

5 - Storage of finished products